SilverAlloy Cd-50Ni3

Nominal Chemical

Composition

INTRODUCTION

Aufhauser SilverAlloy Cd-50Ni3 is a modification of SilverAlloy Cd-50; nickel has been added for improved corrosion resistance in marine environments and caustic media. It is often used for joining carbide tool assemblies because the nickel content increases wettability on tungsten carbide tool tips. Melting range and low fluidity make Cd-50Ni3 suitable for forming larger fillets or filling wide joint clearances. This filler metal contains cadmium.

APPLICATIONS

Aufhauser Cd-50Ni3 is primarily used for joining tungsten carbide to steel.

GENERAL INFORMATION

Chemical Composition| Silver | Copper | Zinc | Cadmium | Nickel |

|---|---|---|---|---|

| 49.0-51.0 | 14.5-16.5 | 13.5-17.5 | 15.0-17.0 | 2.5-3.5 |

PHYSICAL and MECHANICAL PROPERTIES

| Solidus | 1170°F (632°C) |

| Liquidus | 1270°F (688°C) |

| Brazing Range | 1270-1400°F (688-760°C) |

| Specific Gravity | 9.52 |

| Density | 5.02 TO/Cu.In |

| Electrical Conductivity | 18 %IACS |

| Electrical Resistivity | 9.58 Microhm-cm |

| Color | Light Yellow |

SPECIFICATIONS MEET or EXCEED |

| AWS A5.8 BAg-3 |

| AMS 4771E BAg-3 |

| ASME BAg-3 |

| QQ-B-654A, Grade V |

| MIL-B-15395, Grade V |

| ISO 3677: B Ag 50 Cd Zn Ni 635-385 |

| BS 1845 AG 9 |

| NFA 81-362, 50 A2 |

| UNS P07501 |

| EN 17672 Ag 351 |

StANDARD SIZES AND DIAMETERS |

| Diameters: 1/32", 3/64", 1/16", 3/32", 1/8" |

| Sizes: 1, 3, 5, or 50 Troy oz. |

PROPERTIES OF BRAZED JOINTS

Generally, the joint strength using SilverAlloy Cd-50Ni3 will surpass the strengths of the base metals. Strength is a function of the base metals being joined, type of joint, design of joint, joint clearances and brazing procedures. The recommended maximum operating temperature for SilverAlloy Cd-50Ni3 is up to 400°F in continuous service and up to 600°F in intermittent service.

ADDITIONAL INFORMATION

When melting, SilverAlloy Cd-50Ni3 passes from the solid state to a mushy or plastic range and progressively to a liquid. The largest portion of SilverAlloy Cd-50Ni3 melts in the upper section of its temperature range. Therefore, the alloy has a good body while in the plastic range and is suitable for building fillets or bridging large gaps. Late melting of the major portion of the alloy also helps minimize any separation of the solid and liquid portions by liquation during melting.

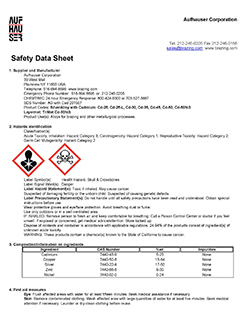

Caution! Contains cadmium. Fumes are poisonous and can kill. Provide adequate ventilation and do not inhale gases and fumes. Read and understand American National Standard Z49.1, "Safety in Welding and Cutting" available from the American Welding Society. The use of brazing fillers containing cadmium may be restricted or banned in certain areas. |