Silver Flux

REFERENCES

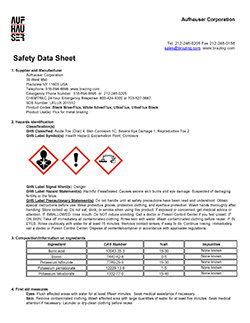

Flux Selection ChartDESCRIPTION

Aufhauser White Silver Flux (also known as the UltraFlux) is a white, creamy silver brazing paste flux used with all standard silver alloys, with or without cadimum (except Bag-19 and BCup-1). It is active and protective to 1600°F (871°C). It was designed for the majority of brazing operations.

Aufhauser Silver Flux is recommended for use with copper and copper-based alloys (except those containing substantial amounts of aluminum), steel, stainless steel, nickel, carbides, precious metals and heat resistant alloys.

The Black Silver Flux (also known as the UltraFlux Black) is recommended where refractory oxides may be present. The boron additives in the Black SilverFlux, (working temperature 1100-1800°F, 566-982°C) are effective where local overheating may occur, as in induction brazing.

SPECIFICATIONS

| FED SPEC | AWS A5.31-91 | AMS | Temp. °F | |

|---|---|---|---|---|

| WHITE SILVER FLUX | O-F-499, Type B | Type 3A | 3410 | 1050-1600 |

| BLACK SILVER FLUX | O-F-499, Type B | Type 3C | 3411 | 1100-1800 |

DIRECTIONS

Aufhauser Silver Flux may be used in concentrated form or diluted with water to a thinner consistency. Heating the flux to 140-180 degrees Fahrenheit (60-82 degrees Centigrade) makes it less viscous and somewhat more reactive. Heat the flux slowly to reduce spattering or excessive bubbling. The raw flux and residues are soluble in hot water (at least 140 degrees Fahrenheit/60 degrees Centigrade). Chipping or grinding is not necessary.

AVAILABILITY

1 and 5 pound jars.