Nickel Brazing Alloy Ni-60

Nominal Chemical

Composition

REFERENCES

Nickel Brazing Alloy ProceduresINTRODUCTION

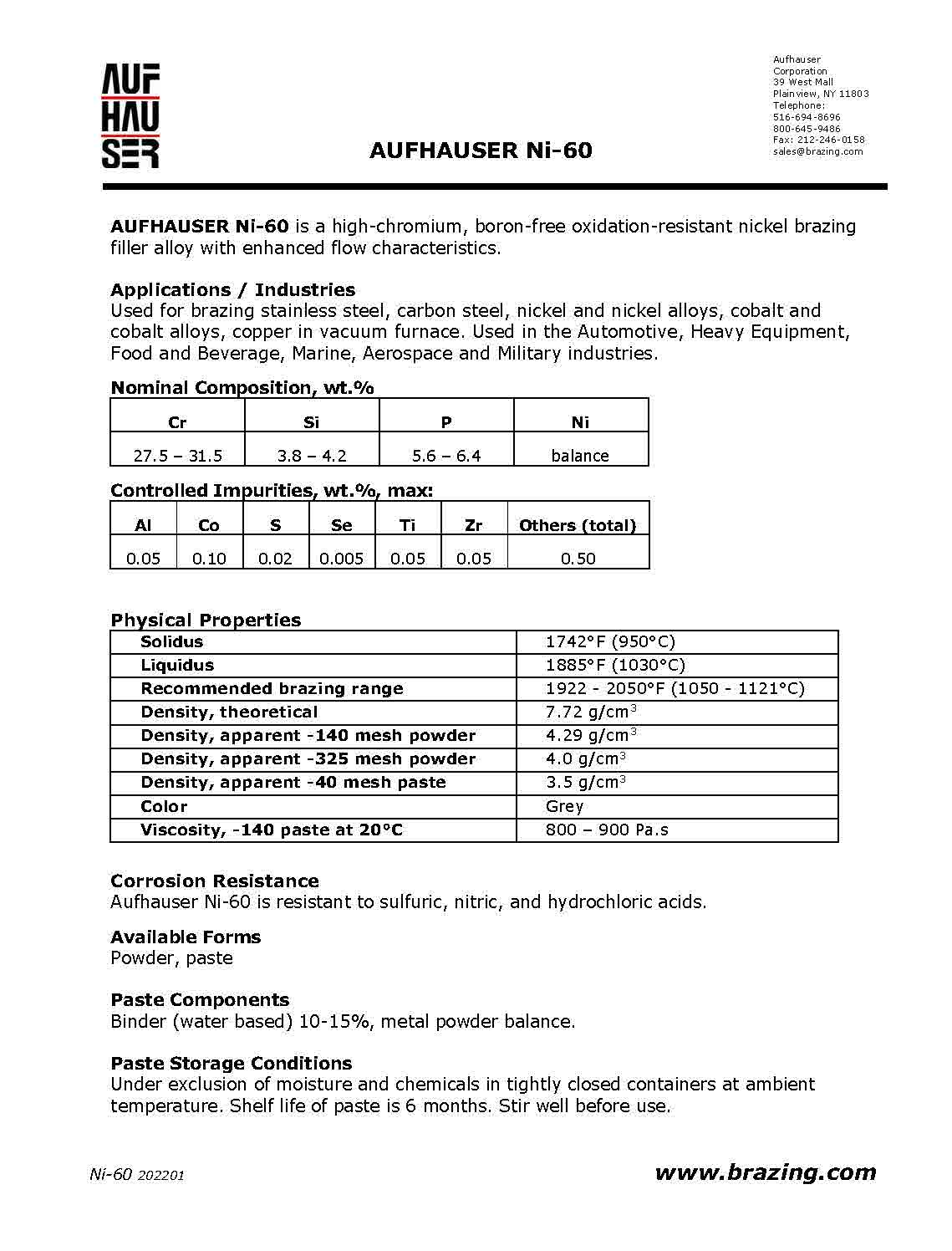

Aufhauser Ni-60 is a high-chromium, boron-free oxidation-resistant nickel brazing filler alloy with enhanced flow characteristics. Used for brazing stainless steel, carbon steel, nickel and nickel alloys, cobalt and cobalt alloys, copper in vacuum furnace.

Industries - Automotive, Heavy Equipment, Food and Beverage, Marine, Aerospace and Military.

Chemical Composition

| Ni | Cr | Si | P | Al | Co | S | Se | Ti | Zr | Other (total) |

|---|---|---|---|---|---|---|---|---|---|---|

| Remainder | 27.5 - 31.5 | 3.8 - 4.2 | 5.6 - 6.4 | 0.05* | 0.1* | 0.02* | 0.005* | 0.05* | 0.05* | 0.5* |

* maximum impurities

PHYSICAL and MECHANICAL PROPERTIES

| Liquidus | 1885°F (1030°C) |

| Solidus | 1742°F (950°C) |

| Recommended Brazing Temperature | 1922-2050°F (1050-1121°C) |

| Density, Theoretical | 7.72 g/cm3 |

| Density, Apparent -140 mesh powder | 4.29 g/cm3 |

| Density, Apparent -325 mesh powder | 4.0 g/cm3 |

| Density, Apparent -40 mesh paste | 3.5 g/cm3 |

| Color | grey |

| Viscosity (-140 paste) at 20°C | 800-900 Pa.s |

Corrosion resistance

Aufhauser N-60 is resistant to sulfuric, nitric, and hydrochloric acids.

Paste components |

| Binder (water based): 10 - 15% |

| Metal powder: balance |

STANDARD SIZES AND FORMS

| Powder, paste |

Paste Storage Conditions

Under exclusion of moisture and chemicals in tightly closed containers at ambient temperature. Shelf life of paste is 6 months. It is advised to stir well before use.