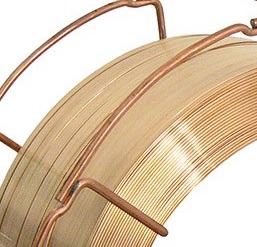

CopperFil

Nominal Chemical

Composition

INTRODUCTION

Aufhauser CopperFil is used for the inert gas welding of copper base alloys. For example: copper-silicon, copper-zinc, and galvanized sheets. May also be welded to steel. This wire is frequently used for joining in artistic foundries (i.e. sculpturing, architectural detailing). The automotive industry has chosen CopperFil over steel wires because of its lower melting point. This lower melting point results in higher travel speeds, better wetting, better gap bridging and even excellent corrosion resistance.

ADVANTAGES

- Joints are made at lower temperature than in gas or arc welding

- Minimizes thermal stress and distortion

- Less susceptibility to cracking

- Soft and ductile weld deposits

- Easy machinability

- Low residual stress

- High strength fillets

- Weld metal is Copper-Silicon bronze

- Excellent corrosion resistance

METALS TO BE BRAZE WELDED

- Copper base alloys: copper-silicon, copper-zinc

- Galvanized sheets

- Steel

APPLICATIONS

- MIG, TIG and oxyacetylene welding of copper, copper-silicon and copper-zinc base metals to themselves and to steel

- Surfacing areas subject to corrosion

- Welding thin steel plates and/or galvanized plates

- Cladding CuMn, CuSiMn and CuZn alloys

- Suitable for cladding cast iron and low-alloyed steels

GENERAL INFORMATION

Chemical Composition| Copper | Manganese | Iron | Silicon | Phosphorus | Others |

|---|---|---|---|---|---|

| > 93 | 0.75 | < 0.3 | 2.8-4.0 | < 0.02 | 0.50 |

ADDITIONAL INFORMATION

Copper and its alloys require a relatively high heat input with shortened welding time. Higher preheat temperatures and faster welding rates than for steel are necessary.

PHYSICAL and MECHANICAL PROPERTIES

| Tensile Strength | 50,000 psi, min. (350 N/mm2) |

| Elongation in 2" | 40% |

| Brinell Hardness | 80-100 |

SPECIFICATIONS MEET OR EXCEED

| AWS A5.7 ERCuSi-A |

| DIN 1733: Sg-Cu Si3 |

| EN 14640: S CuSi3Mn1 - S Cu 6560 |

| EN ISO 24373 |

STANDARD SIZES AND DIAMETERS

| Size | Cast (12" Spool) | Helix (12" Spool) |

|---|---|---|

| 3/32 or 1/8 x 36" rod | N/A | N/A |

| 0.035" dia. x 30 lb. spl | 15-40" | < 1" |

| 0.045" dia. x 30 lb. spl | 15-40" | < 1" |

| 0.062" dia. x 30 lb. spl | 15-40" | < 1" |

GMAW (MIG) Parameters (DC Reverse Polarity) Electrode Positive Spray transfer

| Wire Diameter | Amps | Volts | Argon (cfh) | Wire Feed (ipm) |

|---|---|---|---|---|

| 0.030 | 130-150 | 21-23 | 25 | 460-500 |

| 0.035 | 145-185 | 23-25 | 30 | 400-440 |

| 0.045 | 195-215 | 26-28 | 30 | 280-310 |

| 1/16 | 260-280 | 27-30 | 40 | 150-210 |

GTAW (TIG) Parameters (DCSP)² Electrode negative or ACHF

| Material | 2% Thoriated² | Filler Wire Size | Amps (DC) | Amps (AC) | Gas Cup | Argon (cfh) |

|---|---|---|---|---|---|---|

| 1/16" | 1/16" | 1/16" | 70-150 | 70-150 | 3/8-1/2 | 15 |

| 3/32"-1/8" | 3/32" | 3/32" | 150-200 | 140-230 | 7/16-1/2 | 15 |

| 3/16"-1/2" | 1/8" | 3/32"-1/8" | 230-400 | 225-320 | 7/16-1/2 | 20 |

| 1/2"-1" | 3/16" | 3/16"-1/4" | 325-500 | 290-485 | 1/2 | 25 |