Nickel Brazing Alloy Ni-P-Cr

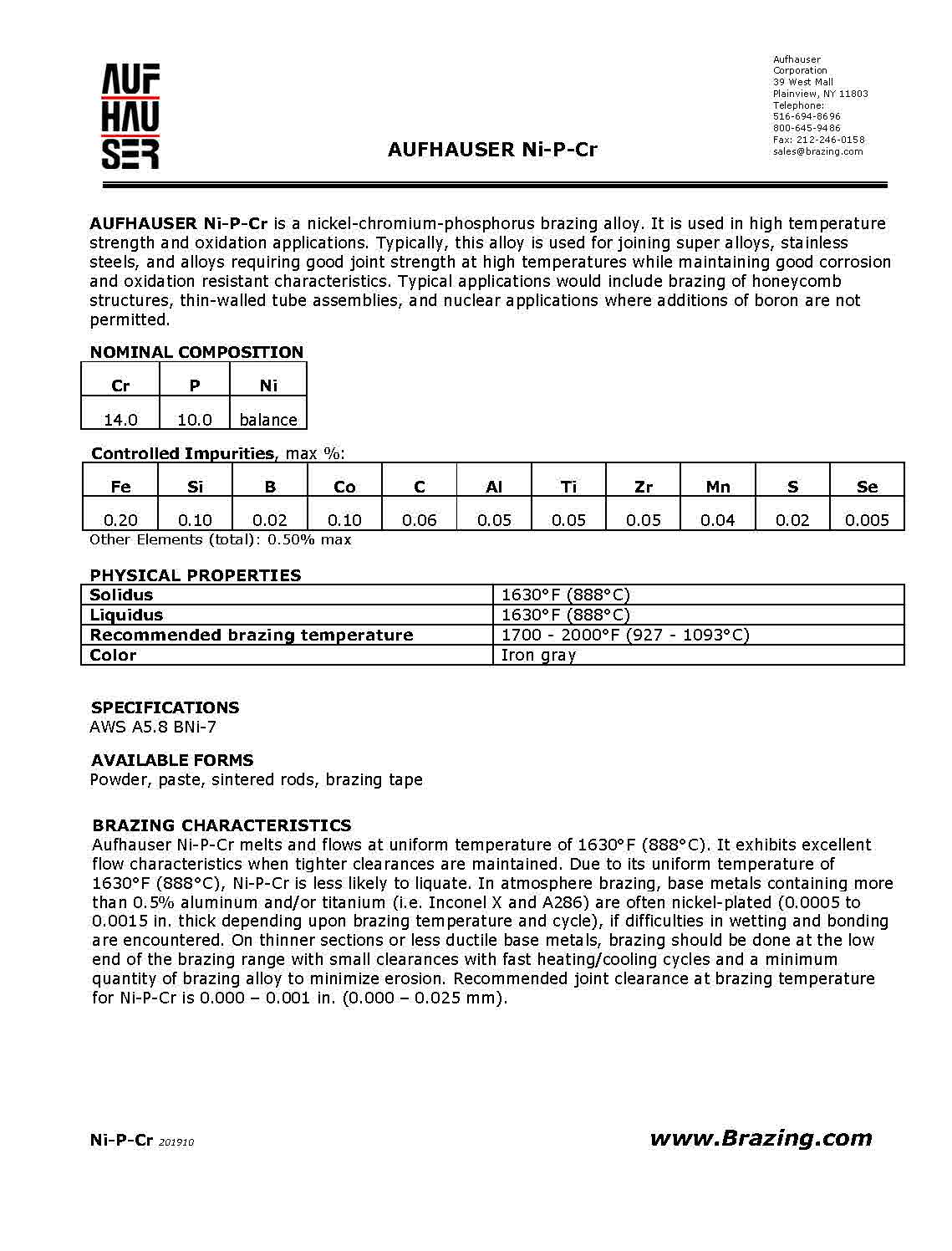

Nominal Chemical

Composition

REFERENCES

Nickel Brazing Alloy ProceduresINTRODUCTION

Aufhauser Ni-P-Cr is a nickel-chromium-phosphorus brazing alloy. It is used in high temperature strength and oxidation applications. Typically, this alloy is used for joining super alloys, stainless steels, and alloys requiring good joint strength at high temperatures while maintaining good corrosion and oxidation resistant characteristics. Typical applications would include brazing of honeycomb structures, thin-walled tube assemblies, and nuclear applications where additions of boron are not permitted.

BRAZING CHARACTERISTICS

Aufhauser Ni-P-Cr melts and flows at uniform temperature of 1630°F (888°C). It exhibits excellent flow characteristics when tighter clearances are maintained. Due to its uniform temperature of 1630°F (888°C), Ni-P-Cr is less likely to liquate. In atmosphere brazing, base metals containing more than 0.5% aluminum and/or titanium (i.e. Inconel X and A286) are often nickel-plated (0.0005 to 0.0015 in. thick depending upon brazing temperature and cycle), if difficulties in wetting and bonding are encountered. On thinner sections or less ductile base metals, brazing should be done at the low end of the brazing range with small clearances with fast heating/cooling cycles and a minimum quantity of brazing alloy to minimize erosion. Recommended joint clearance at brazing temperature for Ni-P-Cr is 0.000 - 0.001 in. (0.000 - 0.025 mm).

Chemical Composition

| Nickel | Chromium | Phosphorus | Others (total *) |

|---|---|---|---|

| Remainder | 14.01 | 10.0 | 0.50 |

| Fe | Si | B | Co | C | Al | Ti | Zr | Mn | S | Se |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.20 | 0.10 | 0.02 | 0.10 | 0.06 | 0.05 | 0.05 | 0.05 | 0.04 | 0.02 | 0.005 |

PHYSICAL and MECHANICAL PROPERTIES

| Color | Iron gray |

| Liquidus | 1630°F (888°C) |

| Solidus | 1630°F (888°C) |

| Recommended Brazing Temperature | 1700-2000°F (927-1093°C) |

SPECIFICATIONS MEET OR EXCEED |

| AWS A5.8 BNi-7 |

STANDARD SIZES AND FORMS

| Powder, Paste, Sintered Rods, Brazing Tape |